Between K-pop and tradition – The influence of Korean culture on product and vehicle design

Mechanical engineer and safety technician Manuel Löwer from the University of Wuppertal on the successful cooperation with Hongik University in South Korea

In Korea, design means both craftwork and the design of industrial products that enjoy a high reputation in a country that developed into an industrialised nation. With its quality in industrial production, Korea became Asia's leading culture alongside Japan and found its way into Europe and the United States with consumer goods from well-known brands such as Samsung and LG. The situation is similar with transportation design. Thanks to their design, technological innovations and quality, Korean vehicles are attracting an expanding clientele - in our country as well. The Hongik University in Seoul is one of the centres of excellence for internationally successful designers. Manuel Löwer, professor of product safety and quality at the School of Mechanical Engineering and Safety Engineering at the University of Wuppertal, has been building up constant cooperation with Asian universities and this design university in particular since 2006. “It is a cooperation between mechanical engineering and safety engineering that extends across various modules in four degree programmes at the School of Mechanical Engineering and Safety Engineering. I have been working closely with my local colleagues since 2006, back then at RWTH Aachen University, where I still offer interdisciplinary courses with international collaborations today,” Löwer explains, who has been bringing together the cooperation with the Korean university at both German universities since taking over the chair in Wuppertal in 2017. “Since 2017, our Wuppertal students have also had the opportunity to take part in this cooperation and broaden their academic and personal horizons in the partner country by participating in courses, modules and exchange programmes.”

Best design university in Korea

“In my opinion, Hongik University is currently the best design university in Korea, supported of course by ratings,” Löwer states. It is a comparatively old university, but a very future-orientated one - which can be clearly seen in the development of Korean products over the last 15 years. “Korea is developing its own design language and is shaping entire markets with technological innovations and cultural characteristics, as well as much of the everyday life of the younger generation here.”

Korean designers are now working in all major automotive companies. Although Wuppertal also has excellent training and teaching in design, this is predominantly product design. With his background in the automotive industry and a keen interest in mobility, Professor Löwer particularly wanted to incorporate vehicle design , which has proven its worth over the last 19 years. “The cooperation is based in the field of systems engineering and also in the field of transportation design at two schools of Hongik,” the scientist reports and continues: “The vehicle technology students from Aachen then join us because we often have interesting projects and industrial collaborations from the automotive sector, the mobility sector, in the courses. Accordingly, Wuppertal's expertise in the fields of quality engineering, safety engineering and also constructive mechanical engineering complements this cooperation very well. This interdisciplinarity, enhanced by intercultural characteristics, is a fantastic enrichment for everyone involved.”

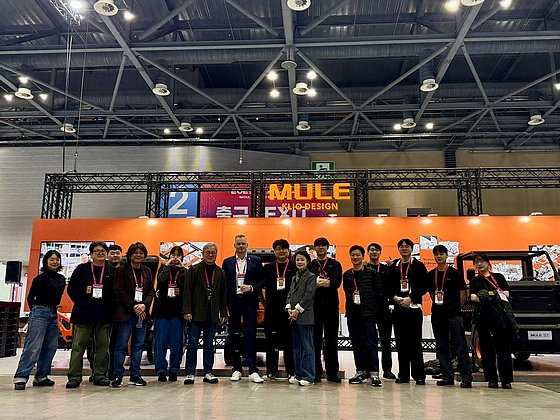

Prof Löwer and cooperation partner of the company Klio in Seoul in front of the exhibition stand, photo: Chair of Product Safety and Quality

Designers and engineers - two mindsets that belong together

“The collaboration between engineers and designers is traditionally always somewhat challenging because different perspectives come together,” Löwer says, describing the joint project work. In the past, they simply designed the machine and then produced an enclosure that was somehow appealing. “Today, you think about it together, i.e., you consider people's requirements and needs from the outset, from the user's perspective, so to speak.” The question of how can I design it in a way that it fulfils the function well, but is also easily accessible, self-explanatory and ergonomically suitable for the user, is an interdisciplinary approach to the project. This approach also makes it very interesting for the students. Engineers in both Wuppertal and Aachen generally work among themselves - in a specialised context - calculating, designing and using lots of formulas, the expert explains, but often lack a broader view of the whole. This is where design, quality and safety come into play and complement the process perfectly.

The University of Wuppertal at top trade fair in Seoul

Manuel Löwer recently took part in the Seoul Mobility Expo in Korea as a representative of the University of Wuppertal, where vehicles were presented that were developed using the expertise from our colleagues in the Bergisch Land. “We presented various vehicle concepts together with the company Klio, a spin-off (a spin-off is the outsourcing of a section or an entire business unit that becomes an independent company, editor's note) from Hongik University. This is a company in which professors from Hongik University are also involved,” Löwer says. The vehicle concepts presented there are particularly suitable for our European market, but also for the American market and emerging countries, thanks to their very high level of sustainability. “The plastic components are made from 100% recycled material, which is why the German company igus GmbH is also involved, as they have a great deal of experience with recycled plastic and its processing. The University of Wuppertal is also contributing the engineering and Klio the design aspect.” The response at the trade fair was consistently positive. “The vehicles were very well received, because you have to realise that it was a very large fair where many German car manufacturers were also exhibiting. We also saw flying taxis there,” Löwer says enthusiastically, “which will still be operated by pilots in Korea from 2025, but will be remote-controlled and later autonomous from 2030.”

Recycled plastic and smart design ensure sustainability

Although Löwer is also conducting intensive research into the use of mushrooms, which could replace plastics as a natural product, he says: “For commercial use in problematic areas, we still have to rely on the recycling of technical plastics in the short and medium term. We are therefore endeavouring to give plastics a second life in the interests of sustainability.” The particular advantage of the vehicles co-designed from Wuppertal therefore lies above all in their well-thought-out sustainability and the fact that these vehicles are at the lower end of the spectrum of what customers want to spend on transport and mobility in monetary terms. The vehicle also scores highly in terms of flexibility, as different applications can be covered with specific superstructures based on the basic structure. “Even the conditions for registration in Europe or America have been considered right from the start,” explains the expert, “so we have a wide range of countries and possible uses.” In the end, the vehicle can be dismantled much more easily, almost completely sorted, and returned to the material cycle.

The vehicles with the designation Mule 4B and Mule MC could also conquer the European market in the future. “There are various interested parties who are very positive about the commercialisation of this vehicle in particular and would also like to take it on. It can be assumed that we will see one or two of these vehicles on our roads and in municipal applications in the future,” Löwer says.

Prof Löwer between Mule 4b and Mule MC

Photo: Chair of Product Safety and Quality

Cooperation with different cultural and professional backgrounds

In the course of the collaboration between the German and Korean universities, the lecturers pay close attention to the existing cultural differences, which do not always make work easy. Löwer explains: “When you work with Korean students, you realise that a lot of communication between them is non-verbal. People are often very reserved, they are not so extroverted when it comes to criticising suggestions, they tend to hold back. This behaviour is quite unusual for our students at first, but the cooperation develops over the various phases of the course. The phase from March to May, when we travel to Korea, is not long and until then everything, i.e., lectures and teamwork, takes place online.” There are no teams consisting only of members from Wuppertal, Aachen or Seoul, but there are two of the team players in each of five interdisciplinary teams, and this mixture is a real challenge. “Without ever having met, they have to try to get to know each other and bring their cultural backgrounds together,” Löwer says, explaining the approach. First of all, a modus operandi has to be found. In addition, all teams had to deliver results right from the start. In order to be able to work so effectively, understanding and empathy for the respective project partner must be demonstrated, i.e., a team identity must be developed. “We have found that both the German and Korean students are very open in this respect. The whole thing is all the more difficult because we also integrate industrial partners in this event, in our case Volkswagen, Porsche and Audi. We coordinate the tasks with them in order to create scenarios that are as realistic as possible and the students also have to present to employees from the companies in the design reviews. This gives them direct feedback from the industry.”

Teams meet in person for the first time in Korea

In addition to the challenges mentioned above, which the students have to overcome in a relatively short period of time, there is also an excursion to Korea, where they can now develop their online experience in practice. “They learn very intensively on site and are involved right from the start. We also offer keynote speeches there and have experts from the local industry as well as employees from Audi, Volkswagen etc. as guests. They are also on hand to help and advise the students. There is also a workshop phase in which the students have to get hands-on and build models themselves.” And, of course, they also get to know each other on a more personal level over a Korean meal or an evening out together after previously meeting online. Finally, our students will take on the role of hosts when the Korean group makes a return visit to Wuppertal towards the end of June and the mobility concepts are finalised and presented after another intensive collaboration phase.

For safety engineer Löwer, this long-term cooperation still harbours many interesting surprises, he sums up, because they are constantly learning from each other.

Uwe Blass

Prof Dr-Ing Manuel Löwer studied mechanical engineering/automotive engineering at RWTH Aachen University. He has been head of the Chair of Product Safety and Quality in Wuppertal since 2017.